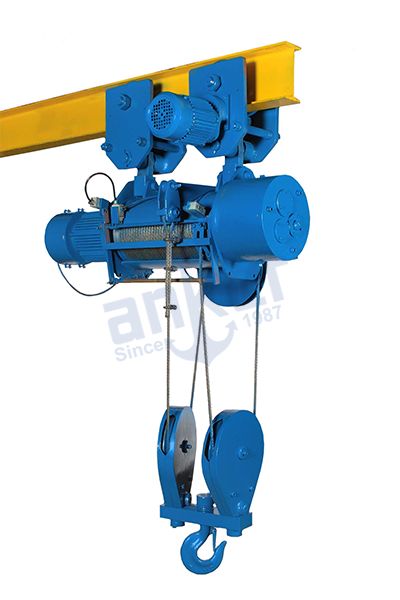

Electric Wire Rope Hoists (Upto 50 Tons)

Home / Electric Wire Rope Hoists (Upto 50 Tons)

“Introduced in the 90s, Our Electric wire rope hoists are unique compared to many of the models available in the market which are non-aligned type design and having off-centre load design.

Indigenously designed and manufactured – Our Hoists are both enhanced & advanced versions of what is available in the market.

Electric wire rope hoist works on the principle of mechanical advantage of Pulleys where wire rope is wounded & un-wounded on the drum to lift / lower the load while travelling trolley moves the load sideways with the help of powered motors.

They offer many advantages over other types of hoists, such as higher lifting capacity, higher speeds and variable speeds, greater durability, lower maintenance costs and enhanced safety features.

They can be operated by a single person using a pendant or a remote control, which reduces labour costs and increases productivity.

Our electric wire rope hoists are available in a wide range to suit your specific needs and applications while offering unmatched lifting performance, with versatility and reliability vital to the operation that suit various sectors including engineering, foundries, automobile & auto ancillary, steel, power, cement, pharma, chemical & manufacturing industries as well as Infrastructure, Mining, Government departments, EPC / Projects, OEM and other Material handling manufacturers.”

Electric wire rope hoists are best suited for reasons such as

– lifting heavier loads than a rope or wire hoist, as the chain is stronger and more durable

– can operate at higher speeds than a electric chain hoist as higher drum diameter increases speed and rope life

– helps in reducing labor costs and increase productivity as it requires less human effort and time to operate

– improves safety and reduces accidents, as it has features such as limit switches, overload protection

Our hoists are designed to provide a dependable and cost-effective solution for lifting needs. With proper care and regular service, Anker hoists can pay for themselves in just two or three years.

Some of the common components of Electric Wire Rope Hoist are:

Consists of Motor, Gearing, Pulleys & Braking system that translates electrical power into vertical motion needed to raise the load.

Electric wire rope hoist works on the principle of mechanical advantage of Pulleys where wire rope is wounded & un-wounded on the drum to lift / lower the load while travelling trolley moves the load sideways with the help of powered motors.

Usha Martin is our most preferred make of wire rope for our Hoists. With minimum strength grade of 1960 or higher as per IS: 2266, Size selection in accordance with the capacity of the Electric Hoist, Load carrying capacity of wire rope & no. of falls onto which the load is distributed to achieve a minimum factor of safety of 5 as per requirements of IS: 3938.

Accurately grooved Rope drum are made from MS Seamless Pipe with bearing hubs / gear hubs concentrically attached to achieve smooth operation of drum reeving / drum winding and uncoling / unreeling of wire rope. Upper & lower load pulleys provide Mechanical advantage and multiply the lifting force and increase the capacity.

The gear train in an electric hoist works in tandem with the electric motor to enhance the lifting power. It ensures that the motor’s speed is appropriately adjusted for the lifting process, providing a balance between torque and velocity.

Gears made of chrome manganese alloy steel material, precise machined, gear hobbed and case hardened – duly annealed to achieve high life.

Load Hook is attached to the load chain or lower block attachment and it is responsible for securing the load during lifting operations, ensuring safety.

Lifting lug connects the electric hoist to a fixed structure or lifting appartus / monorail trolley, providing a secure anchor point for the hoist.

Powers the hoist’s movements and include motors, brakes, controllers and power supply lines.

The interface used by the operator to direct the hoist’s movements and lifting operations.

- Designed in such a way that even a semi-skilled labour can operate and move materials without much oversight or supervision.

- These hoists are ideal for working in both safe and hazardous areas, as they help move products along the production lines smoothly and efficiently

- Robust Design ensures longer life of the equipment

- Higher efficiency results in less power consumption to lift the load in comparison to the competitors

- Each hoist / product is rigorously tested to 25% overload

- Designed with a minimum factor of safety of 4 (four).

- Available from a range of 0.25 ton to 50.0 ton and a lift spanning more than 100 meters, anker electric wire rope hoists caters to wide range of customers for their varied lifting & handling needs

- Anker hoists are known for their versatilty and are available for light duty, medium duty and heavy duty models for relevant tasks at hand

- Hoists are available with a minimum class factor of M4 as per ISO / FEM standards

- Robust design ensures less maintenance and Modular construction of hoist enables ease of maintenance whenever required

- Gears & axles made of high strength chrome manganese alloy steel material

- Improved Hook approach compared to wire rope hoists leading to higher working area

- Increased safety due to anti-fall and anti-tilting mechanism adopted in the cross travel arrangement, hooks with safety latch, fail-safe braking mechanism and low control voltage in the operators’ hand (24 Volts)

- Ensures labor cost saving and improved well being of the workers – who will experience less strain and fatigue.

- Due to remote operation in electric hoists – manpower can lift the goods from a safe distance ensuring safety.

- Our electric wire rope hoists offer the potential to switch to automated operations, enhancing their flexibility to cope with changing industry needs

- Reduced wire rope wear due to adequate drum & pulley diameters and spring loaded rope guide mechanism with optimized reeving in accordance with safety factor calculations

- Deep grooved drum to ensure accurate sitting of wire rope – increases life

- Heavy duty Hooks as per ISO: 15560-2005

- Heavy duty self actuating electromagnetic disc brakes

- Gears made of chrome manganese alloy steel material, precise machined, gear hobbed and case hardened – duly annealed

- Electric hoist can be supplied as stand-alone type or with Monorail Travelling Trolleys including Pull-Push type, Geared type and Electric travelling trolley as well as with crab type suspension for double girder eot cranes applications

- Hoists can be customized for speed including dual speed in hoisting as well as travelling motions, reduced headroom requirements, and slipping clutch mechanism

- With coated / plated / galvanized rope for Chemical / Pharma Industries or Food Industries to avoid contamination

- Also available in flame proof / spark proof models to cater to hazardous environment application with gas group II A / II B / II C and for zone 21 / 22

- Two stage Limit Switches – to reduce abrupt stoppage of load

- Electromechanical overload device to increase safety

- Frequency drives for varied speeds – fast and slow in hoisting, cross travel and long travel as per Customer requirements

- Radio remote control for operation at a safe distance

- Load display at Hook point for lifted load information.

- Also available in flame proof / spark proof models to cater to hazardous environment application with gas group II A / II B / II C and for zone 21 / 22.