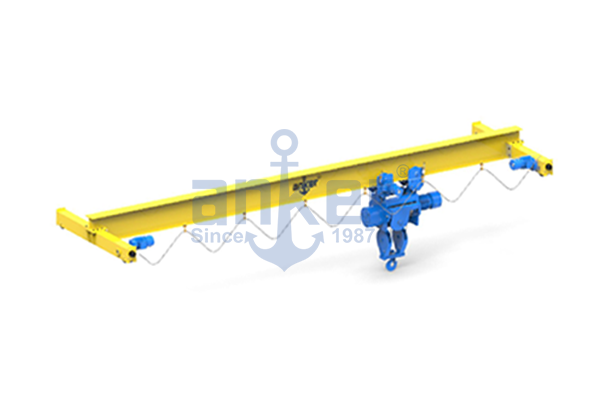

Single Girder EOT Cranes (Upto 15 Tons)

Home / Single Girder EOT Cranes (Upto 15 Tons)

Single Girder EOT Crane is a type of overhead crane that consists of one Main beam and two end carriages. The main beam supports the hoist & trolley, which can move along on the bottom of the beam flange. The end carriages are attached to runway rails, which allow the crane to travel along the length of the workshop.

Single Girder EOT Cranes are maximally used for light loads upto 10T and spans usually upto 20 mtrs. They can be equipped with either Wire Rope Hoist or Chain Hoist as per the load application and Customer requirements. Some of the advantages of double girder EOT Cranes are:

They are versatile cranes used frequently for varied needs in industrial applications

- Single girder cranes has more working area in longitudinal & cross direction than double girder cranes

- It is cheaper and easier to install than a double girder eot crane, as it requires less material and fewer components.

- It has a lower dead weight and a higher lifting capacity than a double girder eot crane, as it has less obstruction from the cross girders and the hoist is closer to the main beam

- It has a simpler structure and a lower maintenance cost than a double girder eot crane, as it has fewer parts and less wear and tear.

- It has a better visibility and a higher safety factor than a double girder eot crane, as the operator can see the load more clearly and avoid collisions with other objects.

Single girder EOT cranes are suitable for industries such as steel, power, manufacturing, mining and cement. They can handle a variety of materials, such as coils, plates, billets, scrap, parts, and machinery. Single girder EOT cranes are designed and manufactured according to the specific requirements of each customer, taking into account factors such as load capacity, span, lifting height, speed, duty cycle, and environmental conditions.

Some of the common components of Single Girder EOT Cranes are:

Primary structural component that spans the width of the Crane. It supports the trolley and hoist and connects to the end trucks.

Located at both ends of the Bridge Girder, these components house the wheels that enable the crane’s movement along the runway beams.

The device that lifts, positions, and lowers the load using a wire rope or chain and a hook.

The device that carries the hoist along the length of the boom. It can be manual or motorized.

Powers the crane’s movements and include motors, controllers and power supply lines

The interface used by the operator to direct the crane’s movements and lifting operations.

- Robust structural design having optimized structural weight matched by skilled workmanship

- Stabilized structural assembly by virtue of adequate length of end carriages

- Optimally designed main girder having maximum rigidity & strength

- Crane components offering high operating safety and reliability

- Enclosed type design of end carriage assembly – giving high strength and protection from dust, weather & birds

- Crane manufactured with with perfection in span & diagonal measurements in precise mechanical engineering tolerances to avoid skewing – resulting in minimum wear & tear

- Crane components offering high operating safety and reliability

- Travel Wheels are duly hardened and tempered made of Carbon steel thus increasing life

- Modular design of Hoist enables ease of Maintenance

- Gears & axles made of high strength chrome manganese alloy steel material

- Improved Hook approach.

- CT Power and Control Supply transmission through Drag Chain or independent C track trailing cabling system along the crane girder for ease of operation

- Customized maintenance platform for maintenance of LT Motors / Crab

- Every motion is equipped with electromagnetic braking mechanism

- Operational control with option of Pendent push button or radio remote control

- Usha Martin make wire rope with a minimum factor of safety – FOS of 5

- All supply cables provided with protective earth conductor

- End carriages are equipped with a jacking pad, sweeper plate and derailment guard as standard features to maximise safety.

- For full length maintenance platform walkway with safety railings provided for a person to easily walk

- Variable options of long and cross travel speeds for customized solutions

- Can be supplied with a Bogie or Articulated End Carriages to reduce wheel load on the gantry

- Two stage Limit Switches – to reduce abrupt stoppage of load

- Electromechanical overload device to increase safety

- Frequency drives for varied speeds – fast and slow in hoisting, cross travel and long travel as per Customer requirements

- Radio remote control for operation at a safe distance

- Load display at Hook point for lifted load information