Trolley (Upto 40 Tons)

Home / Trolley (Upto 40 Tons)

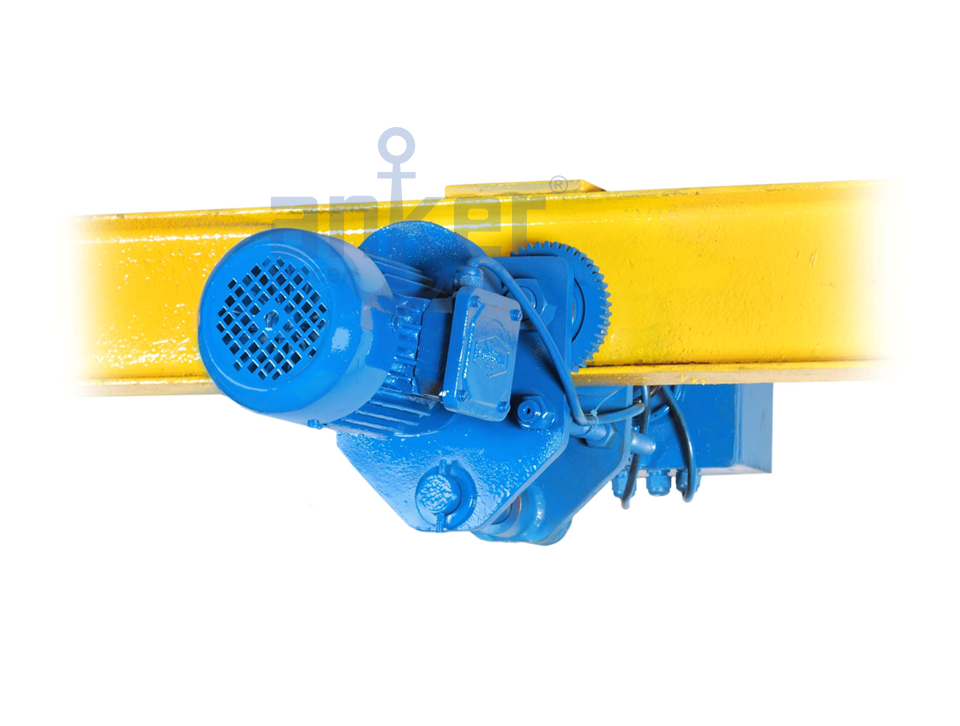

Monorail electric travelling trolleys – commonly known as Electric trolleys operate on a single rail, often referred to as a monorail, and are maneuvered by electric motor and control panel operated by a pendent push button. When operator presses the button – motor is provided power supply which activates a system of gears which in turn propels the trolley wheels along the beam. This allows for faster movement, making it possible to maneuver heavy materials with ease and stability. They are particularly useful in environments where space is at a premium, as the monorail system requires minimal clearance and can be installed overhead, leaving valuable floor space free for other operations.

The versatility of monorail systems is further enhanced by their ability to incorporate features such as curves, switches, and turntables, which can connect to other material handling systems like overhead bridge cranes or conveyors. This makes them an adaptable solution for various industrial processes. Moreover, the electric monorail conveyor systems are particularly beneficial in automated warehouses, where they can move pallets along a closed circuit of electrified rails, connecting different areas quickly and efficiently.

Some trolleys employ a mechanically positive drive system that travels along the rail, incorporating an overspeed and secondary brake to prevent uncontrolled movement, especially down an incline. Electric power to these trolleys is typically provided via a busbar system located adjacent to the monorail, ensuring a consistent and reliable power supply.

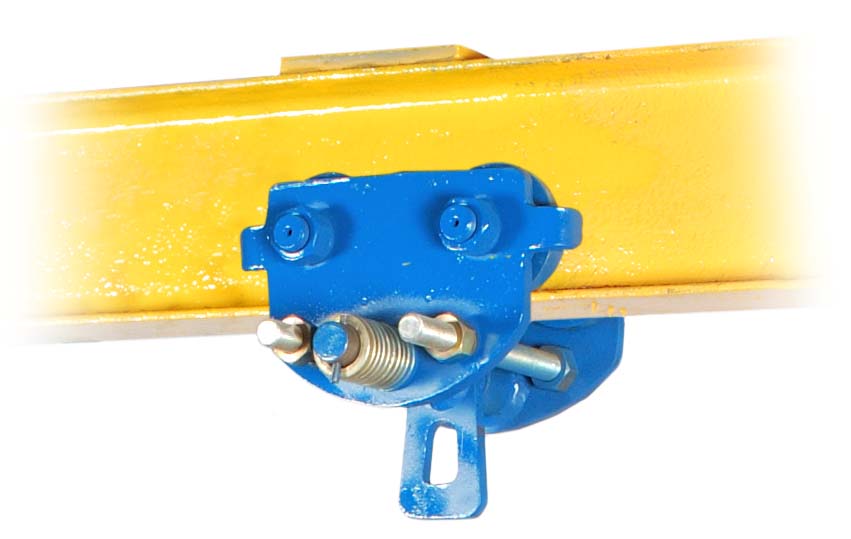

- Anker trolleys are available with adjustable wheel distance to cater to a varied range of flange widths.

- Available in Taper & Flat profile to cater to the Beams manufactured to Indian standards (ISMB, ISWB, ISLB etc.) & International standard like NPB, IPE, UC, UB etc.

- Exact wheel profile ensures better grip & frictional movement along the axis of the bridge girder / beam.

- Anker trolleys are equipped with anti-tilting mechanism to avoid mis-alignment of the trolley wheels in case of wrong handling by the operator – This in turn increases safety for the operator as he doesn’t have to climb up to correct the trolley adjustment frequently.

- High efficiency, low effort / power is required to operate the trolley in comparison to industrial compatriots

- Trolley wheels are manufactured for precision in profile on CNC machines – resulting in higher efficiency

- Rarest of Maintenance in Anker Trolleys

- Trolley wheels are made of Mild steel / Carbon steel to ensure long life as compared to wheels made of cast steel

- Equipped with roller guides to avoid derailing and tilting of mechanism ensuring safety of the labour force

- Accurately pocketed effort wheels to ensure smooth operation of hand chain over the wheels

- Can be equipped with rollers side support as extra feature to enhance stability & avoid tilting, derailing.

- Can be supplied in bogie type system to ensure smooth travel over curved paths

- Also available in flame proof / spark proof models to cater to hazardous environment applications